Factors That Impact Circuit Board Assembly Operations

Assembling a printed circuit board (PCB) requires careful attention to detail at every stage of the process. Many environmental factors can impact the assembly operations and ultimately influence the performance of the final product. For example, exposure to moisture can lead to shorts that require replacement of the entire PCB. Moisture also can cause corrosion that may damage components and shorten their lifespan. This is one of the primary reasons that PCBs must be stored and used in a climate-controlled environment.

Temperature is another important factor that impacts circuit board assembly operations. Different materials expand at different rates, and this can lead to stress on soldered joints. This is particularly true of metals such as copper and brass. Temperature fluctuations can also affect the machinability of metals, and this can make it difficult to properly place components on the board.

A varying ambient temperature can also affect the quality of a PCB solder joint. A poorly formed solder joint can create a weak point that allows water to seep through the joint, causing damage and failure. Keeping the temperature at a consistent level can minimize this effect and maintain a high quality solder joint.

Environmental Factors That Impact Circuit Board Assembly Operations

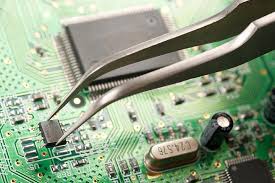

The first step in PCB assembly is to accurately place each component on the PCB according to its pre-determined layout. This can be done by hand or with a pick-and-place machine. This step is typically performed several times to ensure that the components are placed correctly and in accordance with the original layout specifications.

Once the components are in place, the PCB will undergo inspections to ensure that all the connections are intact and that there is enough solder paste to hold them in place. Then, a hot liquid is applied to the surfaces of the components and to the surface of the PCB to bond them permanently. This is usually done using a wave or selective soldering process. In the case of a through-hole board, the soldering process will include drilling holes into the PCB and then inserting wire leads in axial or radial positions.

Some components, such as crystal oscillators, require a very precise temperature to function. These devices are commonly found in micro-controllers and quartz watches, and they function by vibrating at a specific frequency that corresponds with the electronic signal that causes them to oscillate. Extreme levels of humidity can cause these components to fail by exposing the exposed conductors to moisture, which will then form oxides that increase the resistance and shorten the lifespan of the component.

Moisture is a threat to PCB electronics in both the manufacturing and assembly process. It can seep into the components during the manufacturing process or be introduced into the assembly area through condensation. PCBs must be kept in a clean, humid-free environment during assembly to ensure that the components and solder don’t become damaged by condensation.

Many of the chemicals used in circuit board assembly, such as fluxes and cleaning agents, can be harmful to the environment if not handled properly. However, adopting environmentally friendly solvents and implementing responsible waste management practices can help mitigate these effects. Additionally, incorporating eco-friendly PCB assembly processes that use less energy and fewer chemicals can improve the industry’s ecological footprint and reduce its impact on the world’s ecosystems and human health.